The heat sink is the cooling guy who normally brings everything under control. Let’s elaborate on the statement above. The heat sink is a component in the device which usually drains away the heat from the system.

A system being in operation is absolute to produce heat. This is pretty normal, but exposure to the same system to heat for more extended periods can be dangerous for the performance and health of the device.

This blog post details the factors to consider when selecting a soldering heat sink. Stay tuned!

Important Considerations When Choosing a Soldering Heat Sink

A soldering heat sink is of crucial importance because if your heat sink doesn’t work correctly, it can directly affect the device’s overall performance. The quality of the heat sink is what its performance largely depends upon. A low-quality heat sink is highly vulnerable and can put the device in a compromising situation besides technical issues.

Surface Area

The larger the surface area, the more efficient the heat transfer. In other words, heat transfer across the heat sink relates directly to the surface area. The greater surface area provides that large medium or ground for the heat to spread evenly and pass away.

For instance, a smaller surface area will be more like a narrow road overflowing with traffic. You can better imagine the situation in traffic jams.

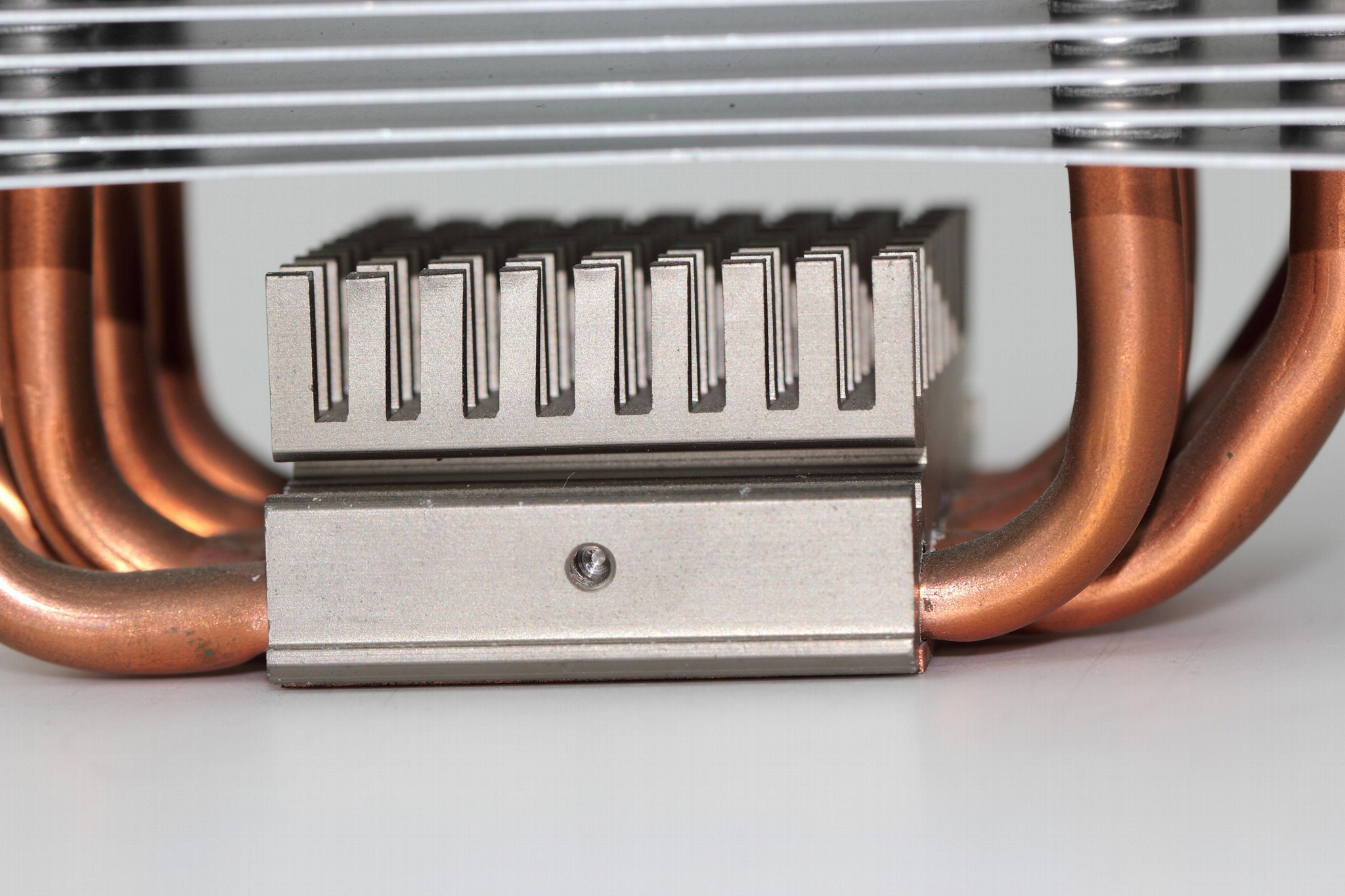

Construction Material

A good make means the best heat sink. If the construction material is a great thermal conductor, the efficiency of the heat sink will multiply. Copper and aluminum are the best metals to use in making the heat sink. Check if the one you choose is made up of any of these too.

The Flatness of the Contact Area

The contact area is where the heat sink connects to the source. The more flatter the contact area, the more swift the passage of heat from the start to the heat sink. If we further explain it, it means if the contact area is incredibly flat, it will facilitate the heat transfer from the source onto the heat sink. So flatness is of vital importance when selecting a heat sink.

Air Flow

A superb and quick airflow is the requirement that marks the function of a heat sink complete. The air is the working fluid that collaborates with the heat sink to carry the heat along the soldering sink and dump it in the environment. If the airflow meets the standards, such a heat sink should be your preference.

Conclusion

A clever fellow constantly researches before choosing a product. This blog post is about aiding you in searching for the most feasible heat sink. When choosing one, there are a few things that you should never ignore. Always check the surface area. A greater surface area makes the heat sink more productive. The flatness of the contact area, airflow, and the construction material of the heat sink are vital factors that are not supposed to be overlooked. A wise selection will make you cheer for your choice.