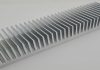

Casing pipes are the backbone of oil and gas wells, acting as protective barriers to protect the wellbore and permit the effective extraction of hydrocarbons from the ground. These tube components, which are normally composed of high-strength steel alloys, are critical in guaranteeing good structural integrity, stability, and durability under a variety of geological circumstances.

Casing pipes serve as a conduit for drilling fluids, preventing well collapse and protecting against external pressures, ensuring that drilling operations run smoothly. The casing is an important component of good construction because it prevents the wellbore from falling in and maintains its structural integrity. The casing acts as a conduit for numerous downhole tools and instruments, improving the overall efficiency and functionality of good operations.

Drilling conditions can be harsh, with high pressure, corrosive environments, and extreme temperatures. The casing pipe is made to withstand these conditions. The American Petroleum Institute (API) and other strict industry standards are followed in their design to guarantee that these vital parts meet specific requirements for size, mechanical properties, and material composition.

What Is The Role Of Casing In Well Completion?

Casing in well completion is an important structural component that stabilizes and supports the wellbore. It helps with the installation of downhole equipment such as packers, pumps, and other tools. The casing separates geological strata, avoids well collapse, and aids in the efficient extraction of oil and gas. Finally, casing ensures the well’s overall integrity and operation throughout the completion and production phases.

Classification of Casing Pipes Based On Their Function in Oil and Gas Wells

Casing pipes play a pivotal role in the construction and integrity of oil and gas wells. They are not one-size-fits-all components; instead, casing pipes are classified based on their function within the well. This article explores the various classifications of casing pipes.

Conductor Casing

Conductor casing, the outermost casing in oil and gas wells, establishes a stable foundation for wellhead equipment. Its large diameter accommodates subsequent casing strings and prevents the collapse of loose surface formations. Typically driven or drilled into the ground, the conductor casing provides initial stability, supporting the overall integrity of the well. This critical component plays a pivotal role in the early stages of well construction, ensuring a secure platform for subsequent drilling operations.

Surface Casing

The surface casing is a critical component in well construction, located beneath the conductor casing. Its major duty is to protect freshwater aquifers from possible pollution. Surface casing, once fully cemented in place, functions as a barrier, inhibiting fluid flow between forms. This casing ensures stability and integrity at the surface, laying the groundwork for future drilling operations. Its precise installation is critical for environmental protection while also ensuring the well’s overall safety and efficiency.

Intermediate Casing

Intermediate casing plays an important part in well construction because it addresses difficult downhole situations. This casing, deployed at variable depths depending on geological difficulties, improves wellbore stability and isolates diverse formations. It is securely cemented, reducing the risk of wellbore collapse in unstable zones. Intermediate casing adds to the well’s overall integrity, allowing drilling operations to go safely and steadily in the face of geological complexity.

Production Casing

Production casing, the final string in well construction, is carefully selected to satisfy reservoir conditions. This casing permits oil and gas extraction from the reservoir to the surface while withstanding production pressures and temperatures. Crucially, it is fixed in place to isolate the production zone and restrict fluid movement. Production casing ensures the well’s integrity and plays an important role in the effective and safe extraction of hydrocarbons from subterranean reservoirs.

Final Words

Casing pipe classification by function is an important part of well construction in the oil and gas industry. From providing fundamental support to permitting efficient production, each form of casing has a distinct role to play in maintaining the stability, safety, and environmental responsibility of oil and gas wells. Understanding these classifications is critical for engineers, drillers, and other stakeholders involved in the discovery and extraction of energy resources.